How quality control elevates Precision aluminum casting performance

Wiki Article

Understanding the Relevance of Light Weight Aluminum Casting in Modern Production Processes

Aluminum casting has actually become an essential component in modern production. Its lightweight and sturdy nature adds substantially to various sectors, from auto to electronics. In addition, advancements in casting strategies improve production effectiveness and quality. As manufacturers look for innovative solutions, the function of light weight aluminum spreading in sustainability becomes progressively important. This discussion will certainly check out the multifaceted significance of light weight aluminum casting and its effects for the future of production. What lies ahead in this developing landscape?The Benefits of Light Weight Aluminum Spreading in Manufacturing

Light weight aluminum casting offers various benefits that boost its allure in contemporary production procedures. One major advantage is its lightweight nature, which leads to reduced energy usage and improved fuel efficiency in transportation applications. In addition, aluminum's exceptional deterioration resistance expands the life expectancy of cast products, making them a lot more long lasting in different settings. The material likewise helps with detailed designs and complex geometries, enabling manufacturers to create elements that fulfill specific requirements.In enhancement, aluminum casting flaunts a relatively reduced melting point, which conserves power during the production process. This quality additionally allows fast cycle times, raising general productivity. The recyclability of aluminum contributes to sustainability initiatives, as recycled aluminum calls for significantly much less energy to process contrasted to main light weight aluminum. Jointly, these benefits position aluminum casting as a necessary strategy in modern manufacturing, accommodating the demands for efficiency, efficiency, and ecological duty.

Applications of Light Weight Aluminum Casting Throughout Industries

While different products are used in production, aluminum spreading has ended up being a critical approach across numerous sectors because of its flexibility and capability. This process is commonly utilized in the auto industry for generating light-weight engine blocks, transmission instances, and numerous elements that enhance fuel efficiency. In the aerospace industry, aluminum casting is essential for creating detailed parts that require high strength-to-weight proportions, adding to improved airplane performance.Moreover, the electronics market counts on light weight aluminum spreadings for warmth sinks and real estates, where thermal management is crucial for gadget longevity. The building and construction industry also gains from aluminum spreading in the form of building elements and structural elements that incorporate visual allure with toughness. Additionally, the consumer goods sector utilizes aluminum castings for kitchenware and showing off devices, leveraging the material's outstanding corrosion resistance and visual coating. Overall, light weight aluminum casting works as a keystone in modern production, sustaining diverse applications across various areas.

The Function of Aluminum Casting in Sustainability

Sustainability has actually become a centerpiece in making methods, and aluminum spreading plays a crucial function in advertising ecologically pleasant options. The procedure of light weight aluminum casting is inherently sustainable due to the material's recyclability. Light weight aluminum can be reused numerous times without shedding its residential properties, greatly lowering energy consumption and resources demands. This recycling process eats just about 5% of the energy required for main light weight aluminum production, causing a remarkable decline in carbon emissions.Additionally, aluminum spreading helps with the production of lightweight elements, which add to power effectiveness in numerous applications, especially in the vehicle and aerospace fields. Lighter automobiles take in less fuel, further minimizing environmental impact. Additionally, innovations in casting methods are enhancing product application, reducing waste in producing procedures. As industries seek to straighten with sustainability goals, aluminum casting emerges as a feasible solution, supporting a round economic climate and promoting accountable manufacturing methods

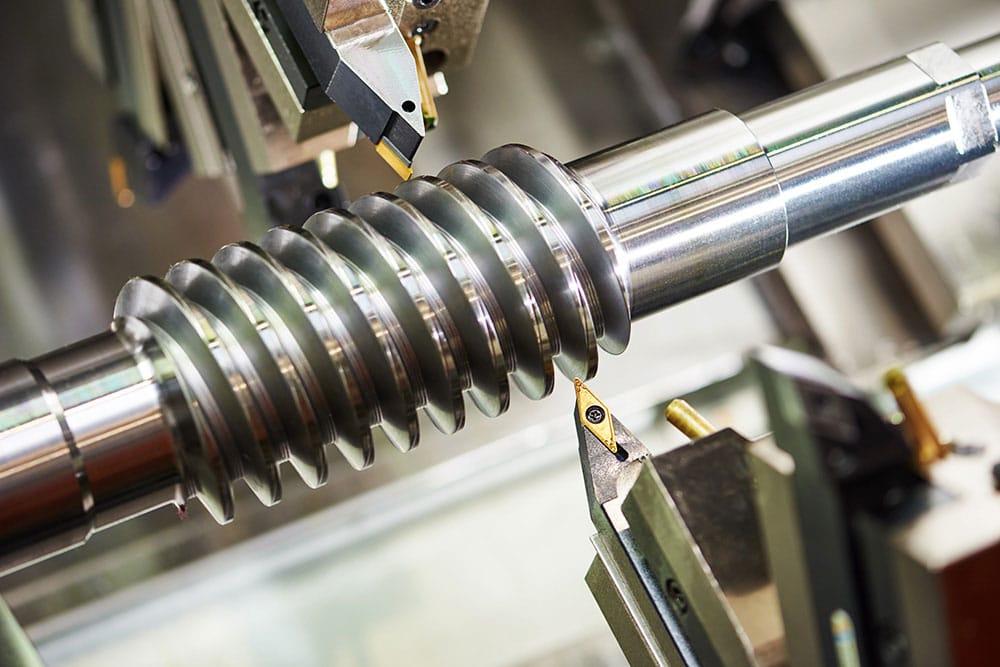

Technological Developments in Aluminum Casting Techniques

As sectors advance, the fostering of cutting-edge innovations in aluminum casting methods has changed making procedures. The assimilation of computer-aided layout (CAD) and computer-aided production (WEB CAM) systems improves precision and performance, permitting complex geometries that were formerly challenging to generate. Advanced melting and spreading techniques, such as die casting and investment spreading, have improved the quality of aluminum parts, minimizing issues and lowering waste. Additionally, the introduction of automated systems and robotics in casting operations has structured workflows and increased performance. These innovations additionally make it possible for real-time monitoring and information analytics, promoting much better decision-making and quality assurance. In addition, the growth of new alloys and warmth treatment processes has increased the performance abilities of cast aluminum products. Collectively, these technical advancements not only maximize manufacturing efficiency however also add to the sustainability of aluminum casting in modern-day production.Future Trends in Light Weight Aluminum Casting and Its Influence On Innovation

Arising trends in aluminum spreading are poised to improve the production landscape, driving development throughout numerous fields. One considerable trend is the combination of sophisticated automation and robotics, which improves precision and efficiency in production procedures. In addition, the surge of additive production methods is enabling for more intricate designs, decreasing material waste and production time. As sustainability comes to be a top priority, the industry's concentrate on reusing light weight aluminum and using environmentally friendly techniques is anticipated to grow, straightening with international environmental goals.The development of wise casting technologies, including real-time tracking and data analytics, is set to boost quality control and operational effectiveness. These developments will assist in the manufacturing of lighter, more powerful, and much more sturdy light weight aluminum elements, satisfying markets such as auto and aerospace. Ultimately, these patterns will not just enhance producing processes but also motivate brand-new applications of light weight aluminum casting, fostering a culture of advancement and adaptability in the marketplace.

Often Asked Concerns

What Is the Background of Light Weight Aluminum Spreading in Manufacturing?

Just How Does Aluminum Casting Contrast to Various Other Steels?

Light weight aluminum casting offers benefits such as lightweight homes and rust resistance contrasted to other metals. aluminum casting. It improves and promotes complex forms power efficiency, making it a recommended selection in different production applications over larger choices like steel or ironWhat Are the Common Problems in Aluminum Casting?

Usual flaws in light weight aluminum casting consist of porosity, shrinking, misruns, and incorporations. These issues can emerge from inappropriate putting techniques, poor mold and mildew style, or infected materials, causing lessened structural integrity and efficiency of the end product.Exactly how Is the Quality of Light Weight Aluminum Castings Tested?

The top quality of aluminum spreadings is examined through techniques such as visual inspections, dimensional dimensions, non-destructive testing strategies, and mechanical home evaluations, making sure that they meet defined requirements for efficiency and structural integrity.

What Are the Security Measures in Light Weight Aluminum Spreading Processes?

Precaution in light weight aluminum casting processes include the usage of individual safety devices, proper ventilation systems, regular devices upkeep, training employees on dangers, and carrying out strict emergency procedures to decrease dangers connected with heats and liquified steel.The recyclability of aluminum adds to sustainability initiatives, as recycled aluminum requires significantly much less energy to procedure contrasted to primary light weight aluminum. While various products are used in manufacturing, aluminum casting has click here actually come to be a critical approach throughout numerous markets due to its versatility and performance. Advanced melting and casting methods, such as die spreading and financial investment casting, have boosted the top quality of light weight aluminum components, reducing flaws and decreasing waste. Arising trends in aluminum casting are poised to improve the production landscape, driving development across different markets. Light weight aluminum spreading has actually advanced since the late 19th century, initially developing with the introduction of aluminum as a lightweight metal.

Report this wiki page